How coating method affect the performance of anti-reflective coating

The anti-reflective (AR) coating can reduce sunlight reflection and let more light come through the greenhouse, which will significantly improve the attainable yield. (see article “AR coating, how and why”) Currently, there are two main methods of AR coating in horticultural greenhouse glass: one is etching method and the other is sol-gel method. Each solution has its unique process and characteristics.

However, before discussing this topic, the background knowledge is needed. Whatever coating technology is used, there are always three main steps: raw glass making, tempering and coating.

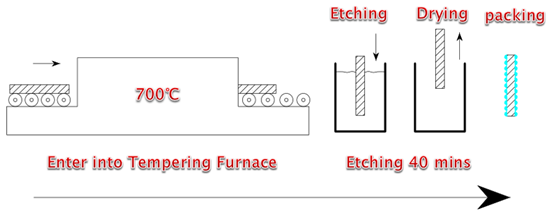

For etching method, the processing sequence is raw glass making, tempering, coating. After the raw glass sheet acquired, it will be sent to the glass tempering furnace for tempering, carrying by a bunch of rollers. Then, in coating process, the tempered glass will be put into an acidic solution pool. On nanometer level, the glass surface will partially be removed, leaving a 100nm-thick coating evenly. After cleaning and drying, the finished AR glass was packed and delivered to the customers. Yuhua diffused glass with AR is using this kind of coating technology.

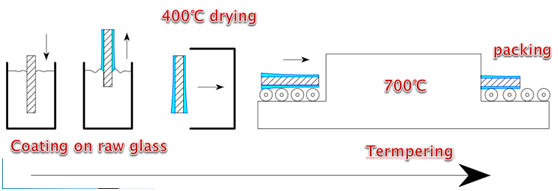

Unlike etching, sol-gel method coating will put a thin SiO2 coating onto the raw glass surface. After drying, the semi-finished glass will be transferred by rollers to the furnace for tempering. In this process, the AR coating is luminated to the glass surface.

According to the demonstration above, we can tell: in etching method, the coating is the original glass itself, while sol-gel coating is another layer on the glass surface. Because the tempering step does not provide fully-melting temperature to the glass, apparently the sol-gel coating will not be as solid as etched coating.

Tags:anti-reflective glass diffuse glass agricultural greenhouses glass greenhouse venlo greenhouse AR glass greenhouses glass agricultural glass horticultural glass #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #GlassManufacturer #invernadero #ArchitecturalGlass #ClearFloatGlass #FloatGlass